Engineering is key to good part design. The basis of a sound design carries through to a quality mold. The 65+ year combined experience of our engineer staff, is capable of solving complex tool design challenges.

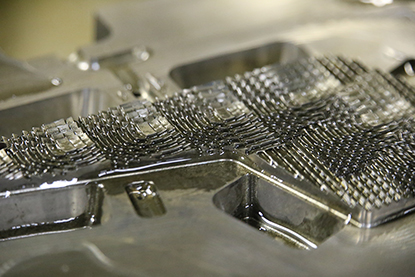

Employing the latest machining technologies aids in producing precision components, reduced lead times and predictable results. Our customers know and trust that we will deliver their parts on time and with the quality results that they expect.

Any types of molds can go from very basic to extremely complex. We can construct molds out of a variety of materials including aluminum, copper and hardened tool steels. We can construct molds for Thermoplastics, Thermosets and Silicone.

We provide services to the automotive, medical, consumer products, DOT/RV Lighting and RV component industries. Our experience in these industries aid our customers in creating quality molded components.

Pick up and delivery is available in Wisconsin, Minnesota, Iowa and Illinois with weights up to 10,000 lbs for our customers convenience.